18 Years Factory Saw Blade For Granite - vacuum brazed blade (key slot) for metal – UPIN

18 Years Factory Saw Blade For Granite - vacuum brazed blade (key slot) for metal – UPIN Detail:

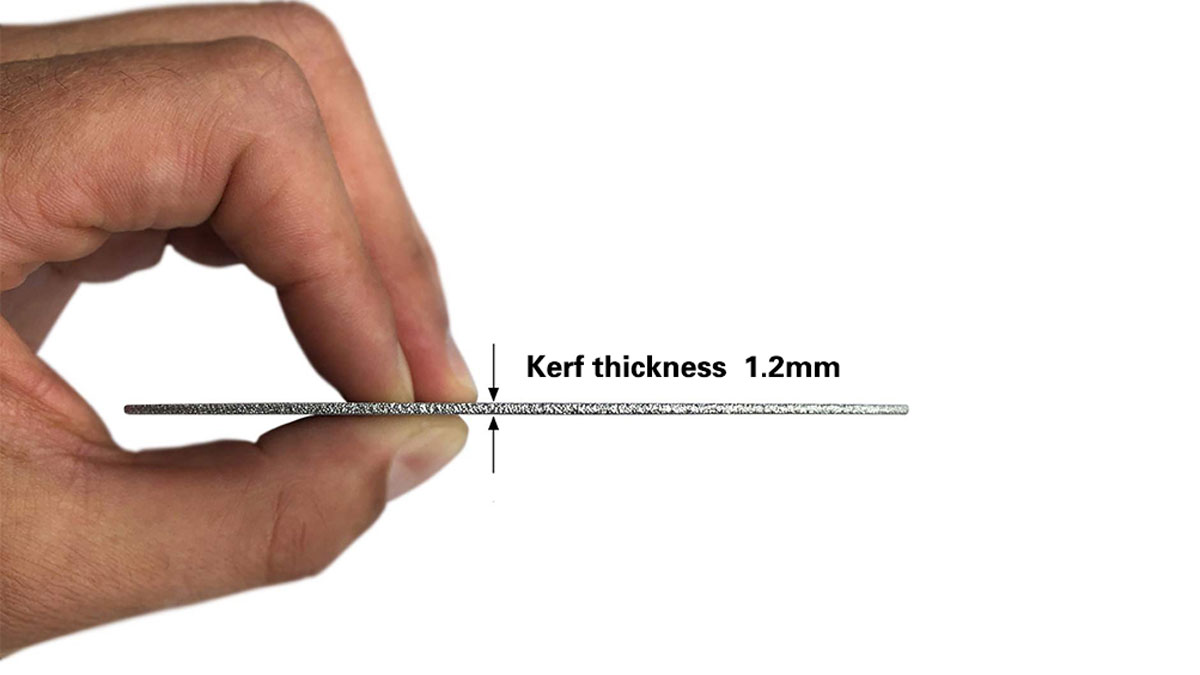

| Product Name | Diameter | Bore | Matrix Thickness | ±0.5segment thickness | Segment Number | ±0.5Diamond coating Height | Matrix Material | Diamond Grit |

| Vaccum brazed blade for iron(key hole) | Φ105 | 16 | 1.2 | 1.4 | 8T | 3 | 65 | 45# |

| Φ115 | 22.23 | 1.2 | 1.4 | 8T | 3 | 65 | 45# | |

| Φ125 | 22.23 | 1.2 | 1.4 | 10T | 3 | 65 | 45# | |

| Φ180 | 22.23 | 1.8 | 2 | 14T | 4 | 65 | 40# | |

| Φ230 | 22.23 | 2 | 2.2 | 16T | 4 | 65 | 40# |

Main Function

Mainly used for all kinds of metal pipes, thin-walled stainless steel, rebar, Angle steel, aluminum and other metals, HDPE and PVC plastic pipes, metal roofing panels, metal plates, with matching adjustable aperture ring

1.They will cut, shape, grind pretty much any material you care to show it.

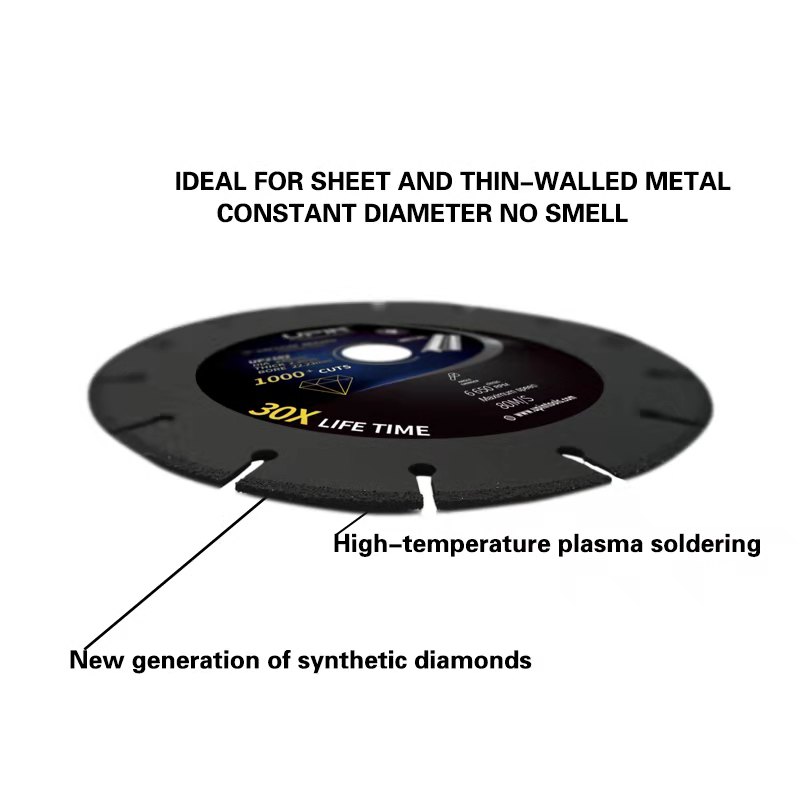

2.It’s why vacuum brazed technology is the basis for “Rescue Blades” used by emergency services worldwide.

3.Offered in two sizes as a utility angle grinder blade. Particularly good for cutting for marble and soft friable stones that break out when using traditional blades.

Also extensively used on fibreglass and other similar composites.

4.The cutting action is very smooth, much more like a “filing” action and not at all aggressive like a traditional sintered diamond blade.

5. Whilst these blades will cut hard ceramics and porcelain, there are better blades for those products. It wouldn’t last long and likely would provide a clean cut on dense porcelain.

With the development of National Urbanization Constriction, many problems have to be solved in the engineering construction and emergency rescue area. High efficiency; safety and convenient cutting the high strength steel or steel-composites structure have become the major problem The application practice shows that the traditional electroplated or multi-layer sintering diamond saw blade carbide saw blades and resin grinding wheel exist abrasive fall off or tools fracture in the process of heavy load and high speed machine, which is due to the low bond strength among the abrasive ,the cutting head and the binding agent Therefore , the disadvantage of the above saw trades have seriously affected the processing efficiency safety aid service life.

Product detail pictures:

Related Product Guide:

Sticking for the perception of "Creating products of top quality and producing friends with people today from all around the world", we constantly place the desire of shoppers to start with for 18 Years Factory Saw Blade For Granite - vacuum brazed blade (key slot) for metal – UPIN , The product will supply to all over the world, such as: Costa rica , Manila , Sevilla , Further, we are supported by highly experienced and knowledgeable professionals, who have immense expertise in their respective domain. These professionals work in close coordination with each other to offer our clients an effective range of products.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!